As a pioneer in additive technologies and a laser specialist, we offer the right technology for every metallic application requirement: Laser Metal Fusion (powder bed-based laser fusion) or (Laser) Powder Bed Fusion, Direct Energy Deposition (DED) and Bio 3D printers

Direct Energy Deposition (DED)

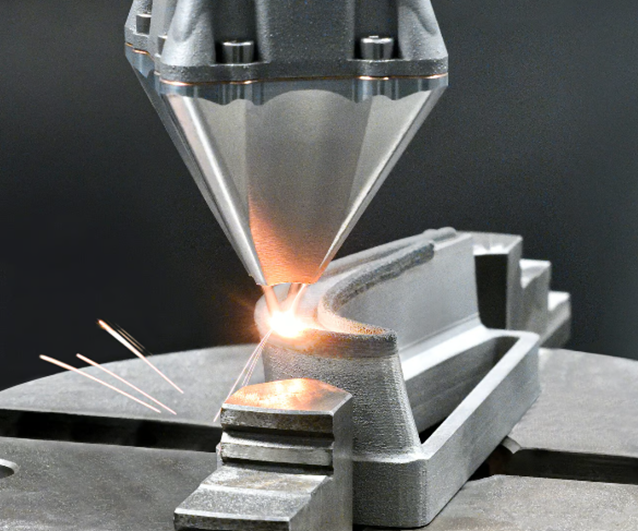

Directed Energy Deposition (DED) is a category of metal additive manufacturing (AM) that utilizes CNC or robotic welding processes to print at high deposition rates but with relatively low resolution. DED systems use an electric arc, plasma, laser or electron beam to melt metal feedstock (wire or powder) into a molten deposit pool. The DED process is typically used for prototyping, low volume production of large, simple parts, and feature addition and repair.

DED based 3D printing is a truly innovative and has emerged as a versatile technology. It opens new opportunities and gives hope to many possibilities for companies looking to improve manufacturing efficiency, build large parts and repair of damaged parts. The technology has the potential to revolutionize industries and change the production line. The adoption of 3D printing technology will increase the production speed while reducing costs.

The speed of the printing process directly affects the throughput and economics. In DED processes, the print speed is correlated to the resolution, measured by the width of the deposition. Powder DED processes tend to be higher resolution and thus have lower print speeds than wire-based DED. Below is a chart representing various DED processes and their approximate print speed vs resolution.

The advantages of Directed Energy Deposition include the ability to control the grain structure, which allows the process to be used for the repair of high-quality functional parts. This does require a balance between accuracy and speed, since higher speeds equal a lower level of accuracy and a less consistent microstructure.

DED allows for the production of relatively large parts with minimal tooling. This process also allows for the creation of components with composition gradients or hybrid structures using multiple materials with differing compositions.

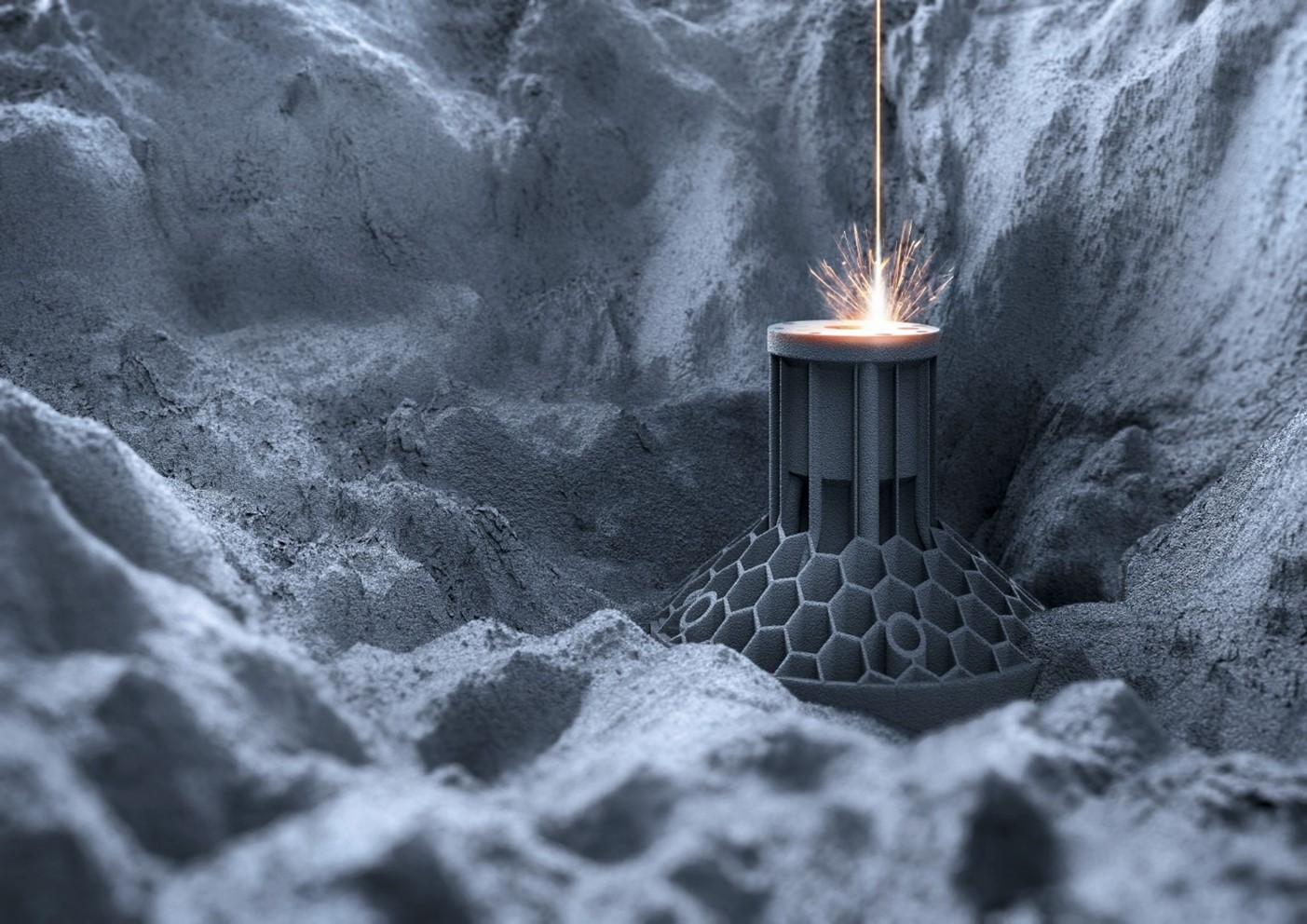

Powder Bed System – SLM 3D printers

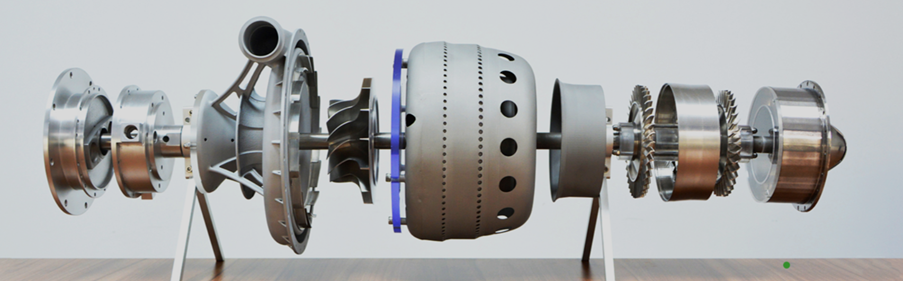

Whether you're in aerospace, automotive, energy, or any industry where precision and innovation are key, Metal Additive Manufacturing offers a revolutionary approach to production with several key advantages.

We develop metal 3D printing and production systems from a materials science perspective with a focus on customer needs. This approach allows us to achieve the mechanical properties and part quality demanded by the industry.

Our principal works successfully with leading aerospace companies across the globe to provide research insights, printer and production solutions for successful outcomes.

We offer industrial metal 3D printers that can be flexibly integrated into existing production environments. From mid-size solutions with a broad material portfolio to ultra-fast four-laser metal 3D printing systems for the production of high-quality series part

Bio 3D Printers

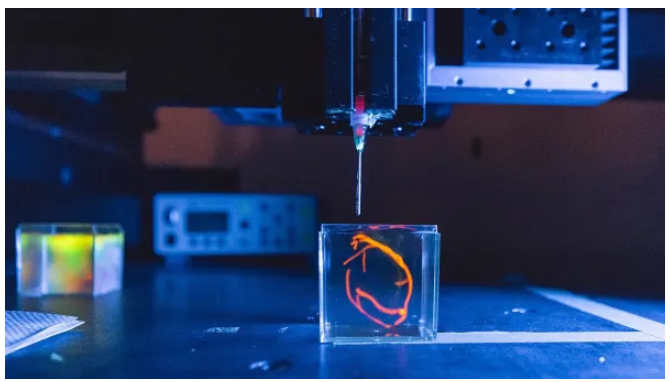

Three dimensional (3D) bioprinting is the utilization of 3D printing–like techniques to combine cells, growth factors, bio-inks, and biomaterials to fabricate functional structures that were traditionally used for tissue engineering applications but in recent times have seen increased interest in other applications such as biosensing, and environmental remediation

Worlds only Robotic bioprinter

We committed to providing the most advanced 3D bioprinting products, services and technologies needed to understand and master biology. We develop technologies that democratize 3D bioprinting - providing the leading researchers in the world the tools they need to create the future of health.

Whether it is developing and utilizing alternatives to animal models, accelerating drug discovery, rethinking regenerative medicine or developing tissue engineered organs to treat diseases previously considered untreatable.

Biology is not square

Complex geometric shapes are abundant in biology. Print strategies to replicate these shapes often require contour printing capability. Our BAB System, with her human-like robotic arm, uses six-degrees of movement to uniquely empower you to precisely 3D print, inject into, and build complex geometries.

Choose from a rich and continuously expanding library of BAB Hands or build your own Hand to accomplish your 3D bioprinting objectives. BAB Hands enable you to print a variety of materials at different temperatures and combinations, fully automate the printing and analytical tasks, locally inject and deposit cells in and on tissue constructs, and conduct scientific experiments with 3D bioprinting. More tools means more capability, more flexibility, and more innovation.